cement ball mills vertical roller mill

2020-06-09T18:06:19+00:00

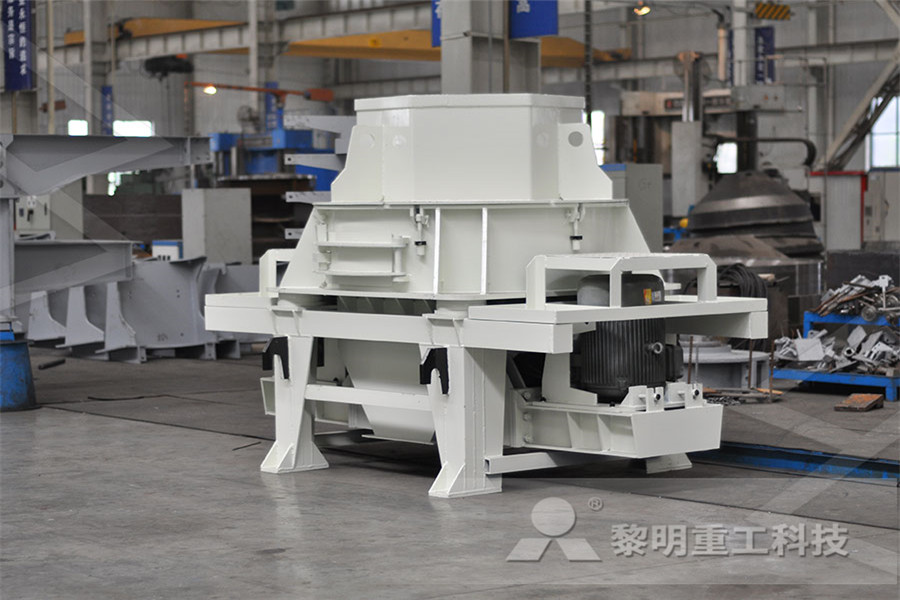

Vertical Cement Mill ball mills supplier

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalentCement grinding Vertical roller mills versus ball millsAGICO is a professional manufacturer of large and medium vertical roller mill equipment The company has a professional team of vertical grinding mill product design, development, manufacturing, installation and debugging, vertical roller mill operation, technical services and other aspects With an annual production capacity of 100,000 tons Vertical Roller Mill ball mills supplier

Vertical Raw Mill for Cement Raw ball mills supplier

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related Vertical roller mill for raw Application p rocess materialsVertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly Vertical Roller Mills

MVR vertical roller mill with planetary Gebr

MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”Cement Ball Mill JXSC Machine The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN

Quality Vertical Cement Mill Cement Ball Mill factory

21 155 T / H Roller Press Cement Mill , 800 3550 Kw Cement Raw MillThe vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement Mill, Vertical Roller Mill Buy Cement Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric Vertical Raw Mill for Cement Raw ball mills supplier

Operation Guide for Vertical Roller Mill in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”Cement Ball Mill JXSC MachineVertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly Vertical Roller Mills

Review on vertical roller mill in cement industry its

A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related Vertical roller mill for raw Application p rocess materials The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN

Ball Mill vs Vertical Roller Mill bulkonline

Vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the oppositeAnd vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choice I think this note,which called what is the difference between vertical roller mill and ball mill can help you21 155 T / H Roller Press Cement Mill , 800 3550 Kw Cement Raw MillQuality Vertical Cement Mill Cement Ball Mill factory A vertical roller mill is a compact unit, making the footprint of the installation smaller and reducing the civil engineering costs when compared to a ball mill system Savings are also made due to the method of construction of Choose vertical roller mill or ball mill in Cement

Vertical Roller Mill In Cement Industry Gravel Mill

Vertical Roller Mill In Cement Industry Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bedDuring operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulators The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”Cement Ball Mill JXSC MachineRoller Mills In Cement Industry In India Review on vertical roller mill in cement industry it Nov 16, 2015 the vrm for cement grinding offers a significant advantage in power savings typically, the vrm uses 50 less power than a ball mill when grinding the same clinker to 3900 blaine vrms are also much more adept at handling hot feed compared to ball millsthe simple and compact introduction on vertical roller mill in cement industry

Review on vertical roller mill in cement industry its

A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related Vertical roller mill for raw Application p rocess materials India: Shree Cement has hired to supply a 11,5000t/day kiln line for its planned Nawalgarh, Rajasthan, cement plant The line will consist of a sixstage preheater and a threesupport kiln The supplier will also deliver an OK vertical roller mill, which it says has a 5 – 10% lower energy consumption than a standard vertical roller millvertical roller mill Cement industry news from Global

MVR vertical roller mill with planetary Gebr Pfeiffer

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice Vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the oppositeAnd vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choice I think this note,which called what is the difference between vertical roller mill and ball mill can help youBall Mill vs Vertical Roller Mill bulkonline